- Digital thickness grid mapping aircraft structure cracked#

- Digital thickness grid mapping aircraft structure software#

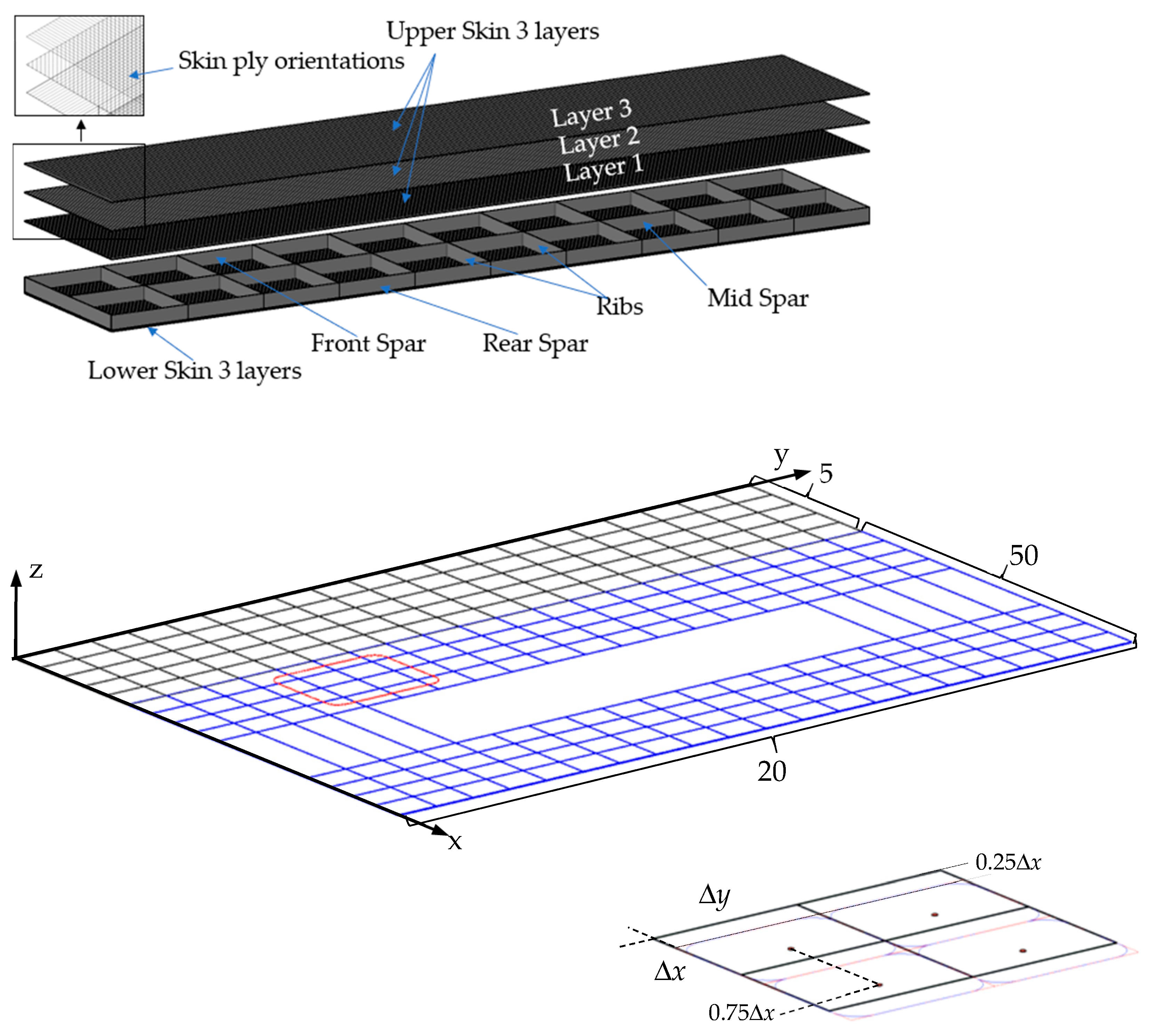

The reason he says it represents value to the Air Force is because once a part is printed and mapped those files can be transferred to another unit when they need to replace the same part.Īllen envisions a near future when units will share these files frequently creating a platform within the community of Air Force structural maintenance, capitalizing on the initial effort being “crowd-sourced” across the fleet and beyond. “For the Air Force, not just the F-15 fleet.” “Being able to reproduce the parts and get the same outcome every time is very valuable,” Jordan said. But when placed in a 100-ton press, that same rubber flows around the mold in a nearly fluid state, which shapes the accompanying part perfectly-every time. The rubber used is very high durometer and does not easily deform, it’s difficult to make any indentation in it even with, for example, a screwdriver. The “smash-box” is a reinforced steel box, lined with a thick rubber mat and closed with a reinforced “lid,” also made of steel. Michael Jordan brings to the shop from his experience at Rogue Aerospace Engineering, the company he runs specializing in helicopter repair and part fabrication when he’s not wearing the uniform on drill weekends. The team relies on that strength to utilize another piece of time-saving technology, a “smash-box.” It’s something Tech. Printed from a carbon filament, it proves vastly more durable than a wood mold. “If you think about carving a tool from wood, that’s something that goes back to the 1950’s, now we are printing parts in a matter of hours and that’s cutting edge.”Īnd this mold is very strong. “We’re definitely using innovation to save time and money,” said Master Sgt. This printed part takes the place of the wood mold.

Digital thickness grid mapping aircraft structure software#

A mold is created using the same software and printed using the brand new 3-D printer located not five feet away. It begins with a better way to assess the part’s exact dimensions-enter a brand new scanning arm with a mounted camera and an attached computer, which can map a part perfectly rendering it in three dimensions. Today, emerging technology can shorten that process to seven hours. They got it done though, as they have for years now-27 man-hours later.

Digital thickness grid mapping aircraft structure cracked#

First, they tried a hard plaster cast, but it cracked when they hammered the sheet metal against it.

Now this flat piece of metal needs to be formed, so they carefully hammer it to shape around a mold. 005 of an inch this way-the acceptable tolerance for this part. Allen says it’s really not possible to get to. Once traced, they cut it from the sheet with hand-tools and file it to match, or as close as they can get. First they cover the part with tape, then carefully cut away a section to give them a rough pattern for the new part, and then trace that part on a new piece of metal. It’s a part that sustains damage in refueling operations when the boom cracks into the aircraft-a somewhat common occurrence-creating an ongoing demand for fairing ribs.Īllen and his structural maintenance co-workers make new ones. One such part is a fairing rib, a semi-circular part originally stamped from a sheet of aluminum with three-dimensional relief.

0 kommentar(er)

0 kommentar(er)